IESL Track Record

IESL has been a successful engineering and technology business for 25 years, during this period we have achieved many milestones in supporting our clients worldwide. Some of these include:

- Completed over 500 projects in well engineering and geomechanical applications

- Awarded 5 patents for technology developed for the areas of well intervention, completion and production

- Developed our international expansion into the North and South American markets

- Achieved ISO 9001 certification

- Developed and taught over 50 knowledge transfer programs worldwide both at academic and industrial level

- Launched our mobile laboratory and rock testing services

- Successfully developed and commercialized a number of completion, drilling and well intervention technologies

- Develop and managed 4 sand management programs lasting an average of 7 years each

Innovation

IESL has been a successful engineering and technology business for 25 years, during this period we have achieved many milestones in supporting our clients worldwide. Some of these include:

- Developed ESP technology for Centrilift’s Coiled Tubing services

- Developed in-house over 70 engineering systems that have been fully commercialized

- Awarded 5 patents in well completion, well intervention and production engineering

- Successfully transferred our CT ESP technology (ReeliftTM) to the WoodGroupESP

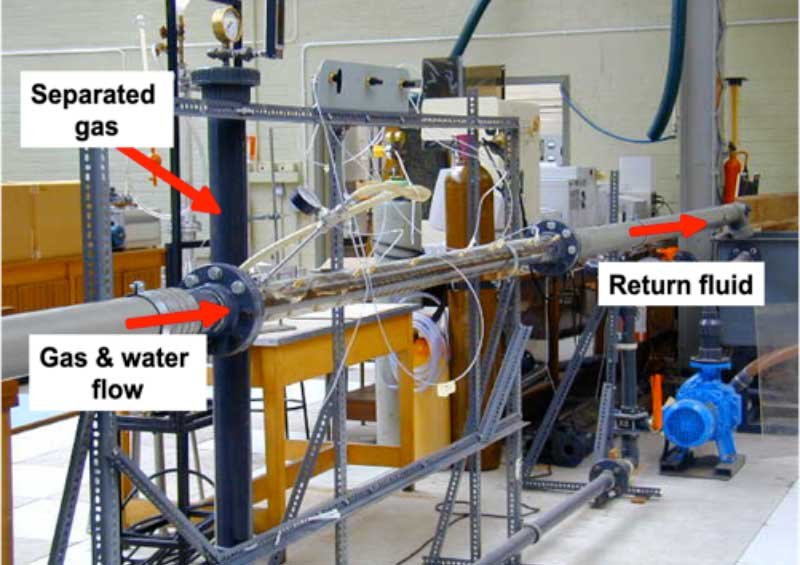

- Successfully developed and commercialized our gas-fluid separation technology (GMASSTM) for drilling and well intervention operations

- Introduced optical sand characterization processes for sizing and sand quality determination

In 2017 we started company’s transformation, shareholding changes and services consolidation were completed. The launch of Strata MecanicaTM, an online portal for data and engineering analysis of geomechanical applications marks IESL’s entry into the digital online provision of its services.

Our clients

Over 25 years of successful operations Innovative Engineering we have worked for many operators, service companies, universities and equipment manufacturers.

Our clients achievements

Innovative Engineering has always developed in-house all its analytical and computational tools for well construction, production engineering, reservoir mechanical performance and water injection. These work resulted in over 70 tools that are used to resolve our client’s challenges. Work on over 500 projects has contributed to extensive validation programs of these tools and achieved ISO 9001 certification successfully. The measure of success is based on the resolution of the client issues, a number of these achievements are illustrated below.

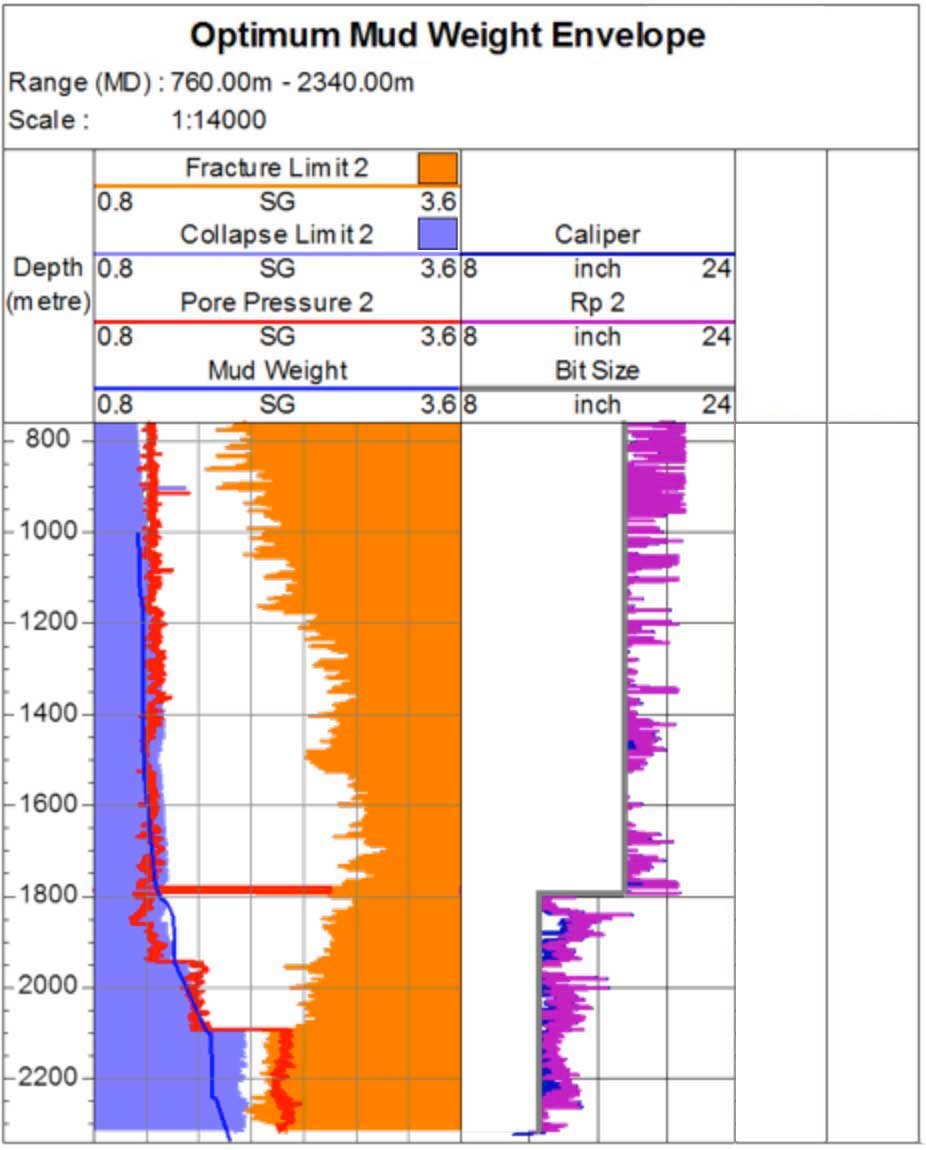

Well Construction – Optimisation of drilling operations

Our Client operates two blocks in the Northern Peruvian jungle. The blocks contain over 14 fields producing from different reservoirs. In-fill drilling development programs required that more complex and longer well paths were used. Drilling planning and design processes identified the need for a detailed understanding of the geomechanical conditions in the basin. Innovative Engineering and our Client’s team carried out a geomechanical characterization of both blocks. Data from over 250 wells was utilised as input for our GeoDRILLTM engineering tool for wellbore stability assessment.

This engineering tool utilises current physics and engineering principles along with empirical data and knowledge to determine the critical parameters for the drilling operations; mud weight limitations, ECD, hole size prediction and identification of potential risk along the proposed well path. The results of the work allowed our Client to:

- Drill and complete new long horizontal wells successfully and with improved efficiency.

- Minimise NPT due to wellbore stability issues while drilling.

- Mitigation of the drilling risk

- Improved well and reservoir isolation reducing the risk of well failure

- Improve completion design and perforation strategy

- Significant cost reduction due to operational efficiencies

GeoDRILLTM is our leading engineering tool for the design, planning and execution of drilling operations. The figure in the following page illustrates a typical output for the determination of the OMW envelope.

Innovative Engineering contributed to our client’s success by:

- Delivering robust and representative results that were easy to apply in the field.

- Developing a large database and knowledge management system for both blocks that allow the client to refer and learn from previous experiences.

- Assisted the client with the well design, planning and execution of its drilling operations

References:

Sorrentino Y., Moreno F., Tovar J., Tapia J. and Lanza H.: “Effective use of Geomechanical Data for Resolving Wellbore Stability Problems in Blocks 1AB and 8, Northern Peru”, SPE paper 108056 presented at the 2007 LATAM conference, Buenos Aires, Argentina

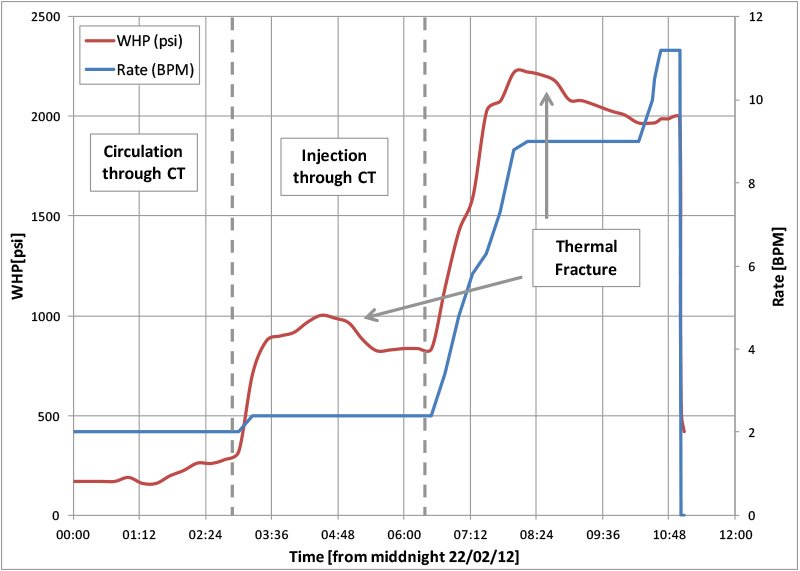

Reservoir Mechanical Performance – Water Injection Optimisation

Our Client operates a field located in the UKCS. The field is being developed using 4 producers and 2 water injectors that will be used for PWRI. Large pre-completion skins (S > 60) indicated poor injectivity for the first injector. Innovative Engineering and our Client’s team worked to address the problem; formation-damaging mechanisms were identified and remedial actions designed and implemented. A thermally induced fracturing treatment through Coiled Tubing was designed and carried out successfully to restore injectivity.

The results of the work allowed our Client to:

- Restore injectivity from 2828 bwpd to > 18000 bwpd.

- Maintain containment of the fracture within the reservoir.

- Ensure on-time field production start-up with adequate pressure support.

Innovative Engineering contributed to our client’s success by:

- Carrying out the design and field execution/verification of the TIF treatment.

- Supporting our Client’s efforts throughout the design and operations.

- Providing post analysis of measured data and fracture location identification.

References: Smith F. Verlinden V., McIntosh K., Tovar J. and Ibukun O.: “Thermal fracturing in high and low permeability sandstone reservoirs in the North Sea”, EAGE 2012, Rio de Janeiro, Brazil

Sand Production Management System – SPMS®

Our Client is the operator of a field located in the North Sea. The field produces from 2 subsea wells and an additional well is utilised as a water injector for reservoir pressure support. In 2009 the lower completion in 1 of the producers failed leading to loss of integrity, massive sand production and stoppage of production. A team of engineers and geoscientists was assembled and a Sand Production Management System SPMS® program was implemented and operated for 9 years. Analytical tools were developed, tested and implemented as part of the program in order to provide the diagnosis of well, plant and flowlines performance.

Innovative Engineering has contributed to our Client’s success in the field based on providing robust engineering and operational knowledge that delivered value by:

- Providing real-time surveillance of over 25 sensors in order to provide timely diagnosis for efficient decision-making.

- Avoiding premature shutdown of the well due to collapse of the completion due to sanding and completion failure.

- Dramatically reducing the inevitable long-term damage to the facilities resulted in cost savings that contribute to lowering the cost per barrel.

- Enabling field on full production for over 5 years (beyond its originally predicted life), 11 mmbo recovered.

- Limiting sand production to 130 tonnes over the 5 years with minimum risk to the asset and environment reducing the number of costly cleanouts required.

- Minimising NPT to < 5% (none of which is related to the production of sand), decreasing deferred production.

- Enabling wells to be produced without skin at maximum PI’s.

- Providing comprehensive results from the flow assurance aspect of the program ensuring well and asset integrity at all times.

- Managing pore pressure through water injection and real-time monitoring of the injectors wells performance.

- Enabling the formation of a knowledgeable management team for ongoing continuity.

References: Tovar J. et al. Publications presented at the Sand Management Network, Aberdeen, Scotland, UK, 2010, 2012 & 2014

Rock Mechanics Testing

Ultrasonic & RLIST® – a) Direct/Compressional measurement, b) Indirect/Shear measurement c) RLIST® measurements

Our client operates several fields in the Paris Basin in France. A continuous water injection program for pore pressure support and reserves recovery is in place. The development and calibration of the mechanical models of the fields were crucial in developing accurate datasets. For these fields, core material from 16 wells were available to provide calibration data, without which the models would not be representative or robust. A test program for rock strength and mechanical properties was developed. Over 400 UCS measurements were taken using Innovative Engineering’s RLIST® (Rapid Low Impact Strength Test) and 500 measurements for rock acoustic response using Innovative Engineering’s Ultrasonic testing capability. The results of the work allowed our Client to determine and characterise the mechanical properties of the rock to:

- Understand the variation and scatter in the different sections of the rock for identification and location of fractures to determine fluid flow and the effects on the production capability.

- Identify the rock quality designation index for fracture identification from logs to help in building discrete fracture models of the reservoir for use in characterising and simulating fluid transport.

- Identify variation in strength across the various stratigraphic sections within the field to aid in the design of fractures and maintain reservoir mechanical performance and integrity.

Innovative Engineering contributed to our Client’s success by:

- Gathering data and calibrating the geomechanical models to get a better understanding of the reservoir mechanical properties and behaviour.

- Providing analysis of the fracture network and rock quality to improve the knowledge of the reservoir fluid flow and the pressure support from injector wells.